WT is committed to promoting sustainable development in the supply chain. We encourage our major suppliers to provide high-quality products and services while complying with national regulations and policies. They must ensure that their products and manufacturing processes adhere to environmental and social responsibility standards. Suppliers are required to prohibit the use of hazardous substances (such as those restricted by the EU RoHS directive), ensure that raw materials do not contain conflict minerals, and sign a Conflict-Free Minerals Declaration.

Additionally, WT encourages suppliers to adopt ISO certifications to enhance quality management. Suppliers are also urged to implement occupational safety measures, labor rights protections, and environmental protection initiatives, working together to establish a responsible and sustainable supply chain.

WT considers suppliers as long-term partners and maintains close communication with them. Through continuous engagement, we promote the implementation of environmental sustainability, social responsibility, and ethical standards. We also emphasize compliance and corporate responsibility in operations, ensuring that suppliers commit to ethical business practices, human rights principles, and corporate integrity.

Self-Regulation of major Supplier Codes of Conduct

The major suppliers have established comprehensive business conduct guidelines to ensure compliance with relevant regulations and international standards.

Supplier Environmental Management and International Standard Certifications

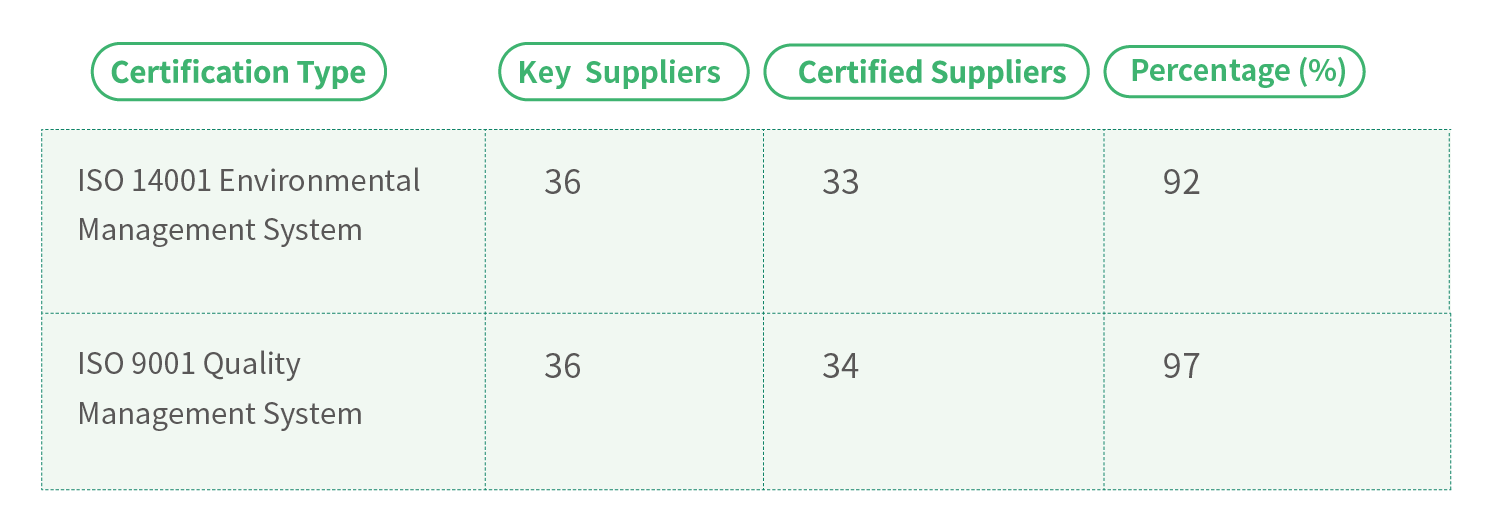

WT places high importance on supply chain responsibility. WT has identified and prioritized 36 key suppliers, which collectively account for over 80% of total revenue. Annually, WT conducts assessments on these suppliers, covering areas such as Responsible Business Alliance (RBA) compliance, restricted substance commitments, and conflict minerals policies. Additionally, the list of key suppliers is reviewed and updated at the beginning of each year.

The key suppliers have adopted ISO certifications to ensure their operations meet international standards. By implementing strict management systems, they enhance operational efficiency and minimize environmental impact.

As of the end of 2024, key suppliers have achieved the following certifications:

|

|

|

Employee Rights and Labor Protection

The suppliers must comply with local laws to protect employee rights, ensuring:

- Respect for employees’ rights to unionize, engage in collective bargaining, and enjoy freedom of association.

- Establishment of communication channels to safeguard labor rights and prevent forced labor, child labor, or discrimination.

Responsible Business Alliance (RBA) Code of Conduct

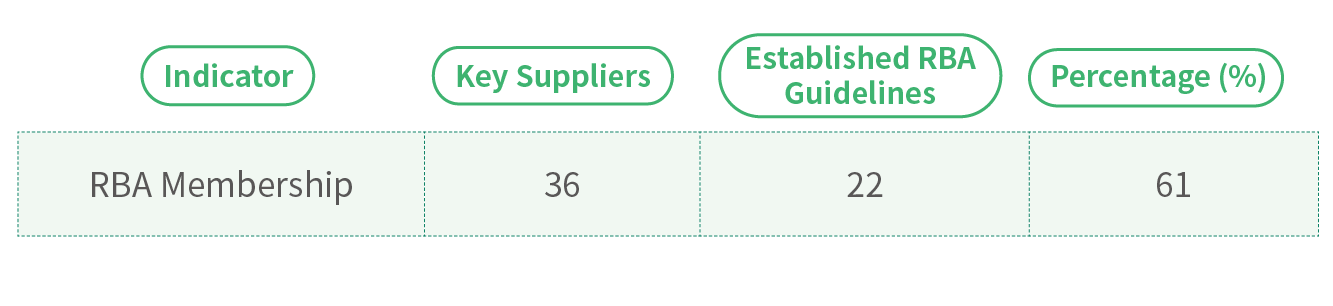

WT supports and adheres to RBA Code of Conduct, striving to improve labor rights, health and safety, and environmental standards to ensure compliance with international and ethical norms.

|

|

As of the end of 2024, WT continuously monitors 36 key suppliers, of which 22 are official RBA members, representing 61% and having established comprehensive RBA guidelines. Additionally, WT actively tracks whether suppliers undergo RBA audits to promote ongoing improvements in labor conditions throughout the supply chain. |

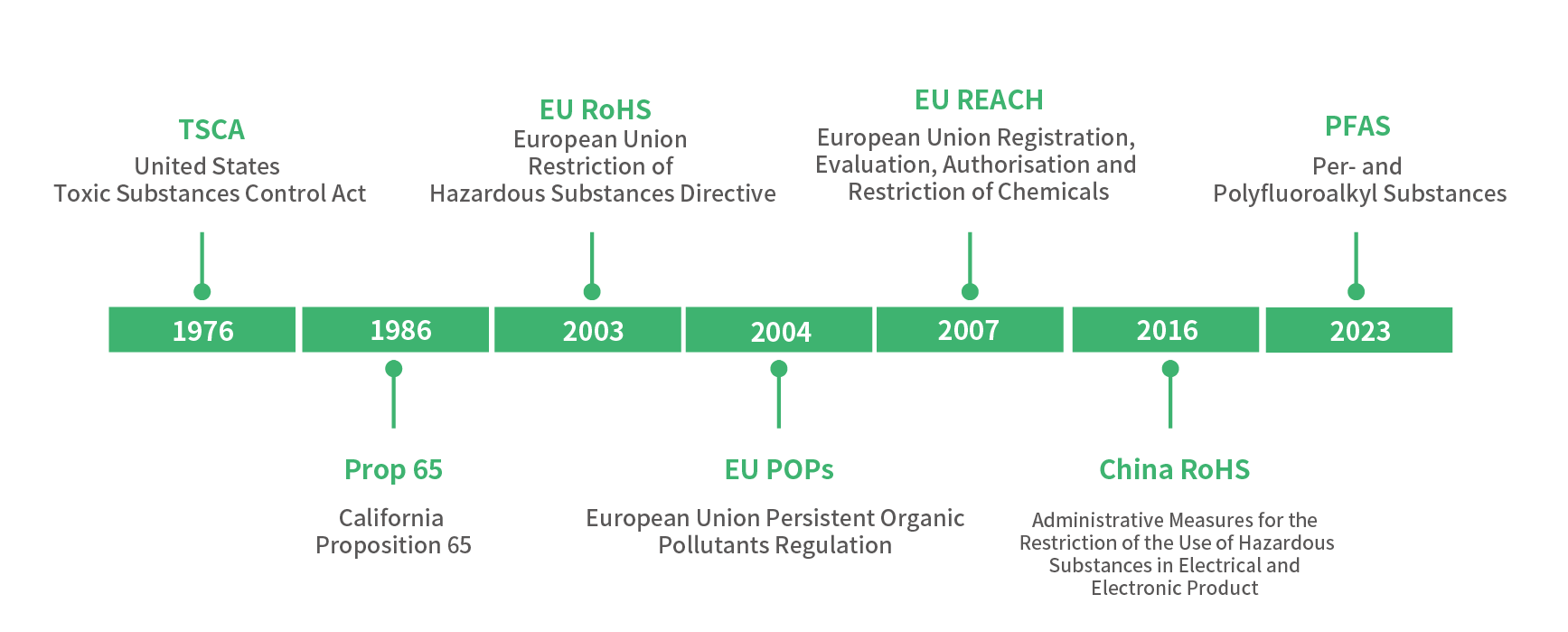

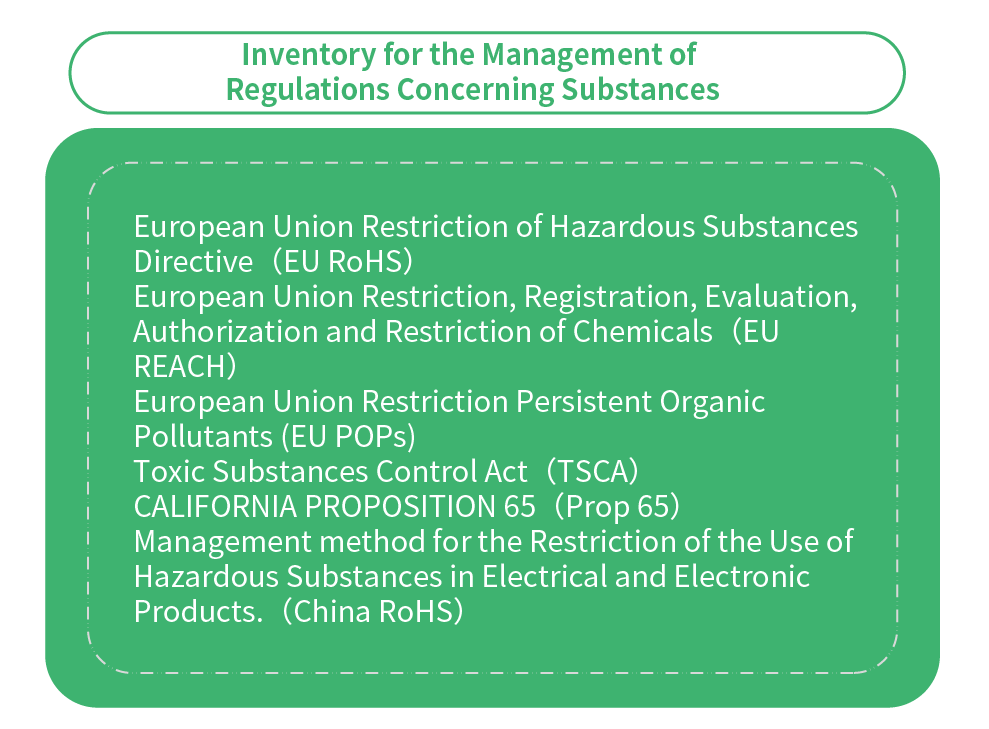

Compliance of Agency Products with Global Substance Regulations

Chemical Management and Product Compliance

With increasing global emphasis on environmental protection, WT continues to monitor regulatory developments and ensures that suppliers’ agency products fully comply with relevant global substance regulations. We actively track and update compliance measures to meet customer requirements.

When customers request material substance lists for products, WT assists in obtaining relevant documentation from suppliers, such as non-use declarations, product composition reports, and third-party hazardous substance testing reports.

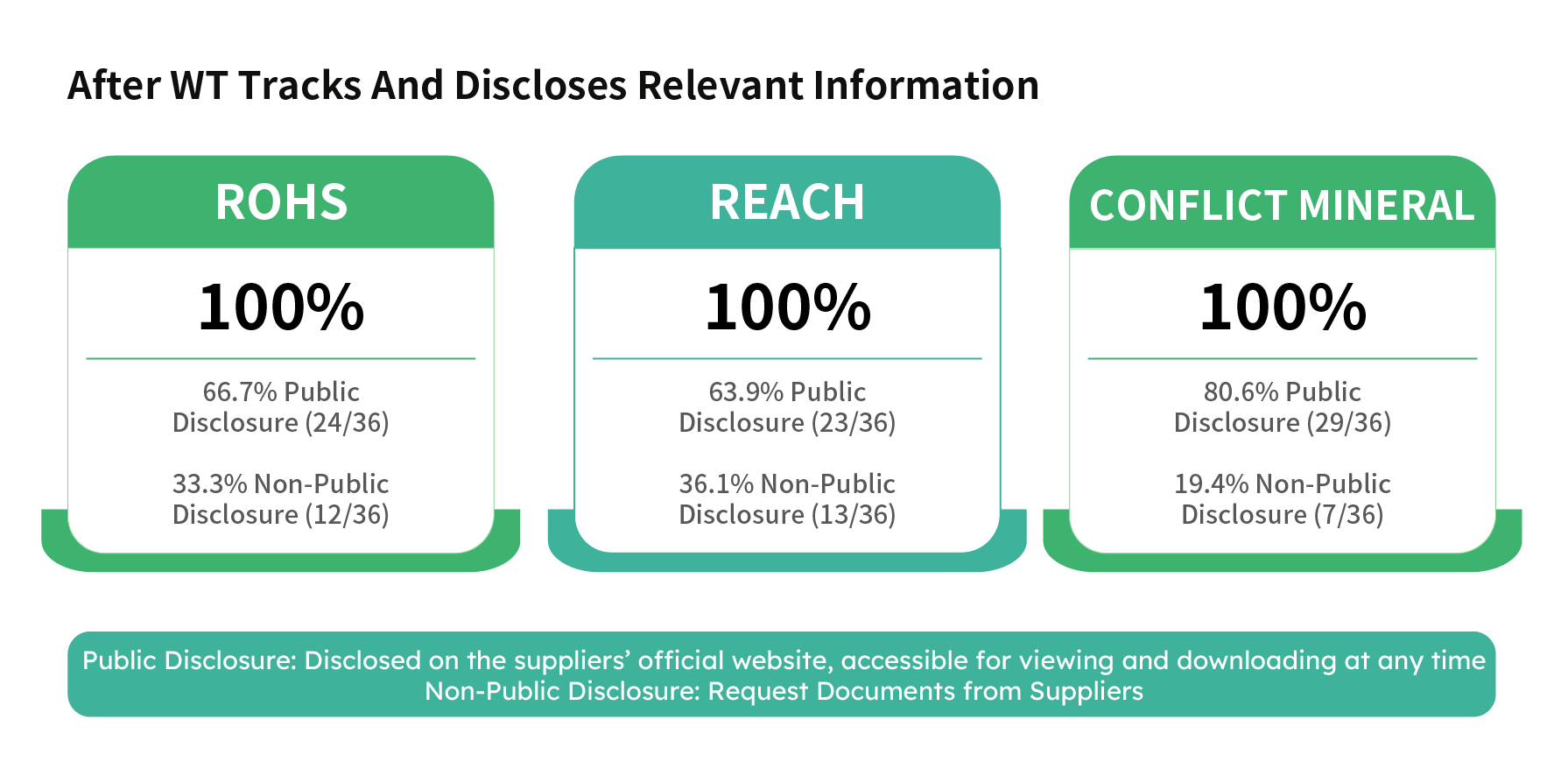

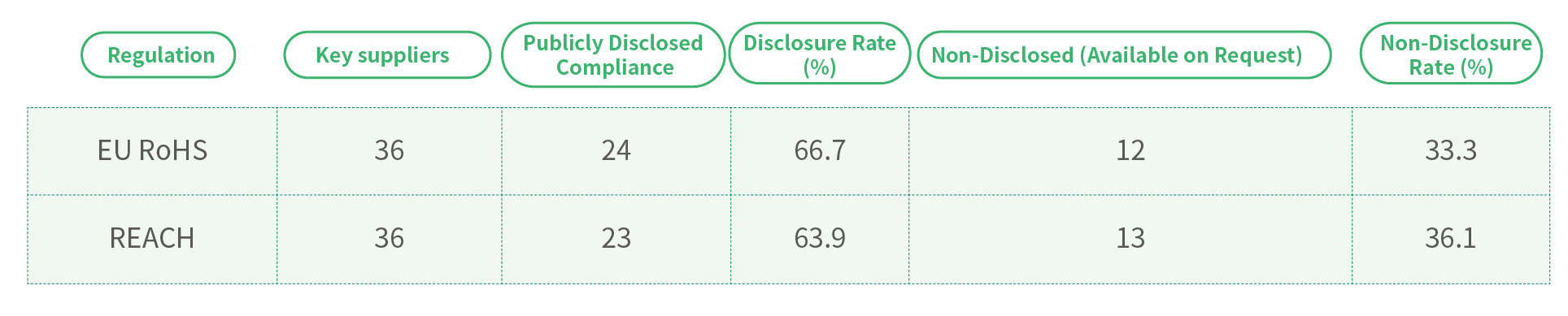

In 2024, all sold products complied with customer chemical management requirements. All of 36 key suppliers publicly declared full compliance with relevant chemical management regulations.

As of the end of 2024, compliance rates of key suppliers are as follows:

|

|

Furthermore, WT is actively implementing system-based management. In the future, when creating new product materials, relevant departments will be notified to obtain the necessary material substance lists (such as product composition reports and third-party hazardous substance testing reports). This will ensure compliance and improve the efficiency of providing relevant material disclosures.

PFAS (Per- and Polyfluoroalkyl Substances) Management

In 2023, the EU introduced a proposal to ban PFAS, a broad class of synthetic chemicals known for their persistence, long-range transport potential, and bioaccumulation risks. These substances pose significant environmental and health hazards, including water pollution.

In industries such as semiconductors, no viable alternatives currently exist, and immediate production cessation is not feasible. Therefore, a transition period of 13-15 years will be implemented upon enforcement of the regulations.

WT continues to investigate PFAS usage in supplier products and discloses this information to customers, aiming to mitigate environmental and health risks.

Carbon Footprint and Net-Zero Emission Goals

In response to global carbon reduction initiatives, WT is dedicated to carbon footprint assessments, aiming to reduce, capture, and reuse greenhouse gas emissions. The long-term goal is to achieve Net Zero Emissions by 2050, transforming carbon reduction efforts into competitive advantages and steadily implementing sustainability initiatives.

The customer requests products with conflict minerals traceability, 100% sourced from qualified smelters

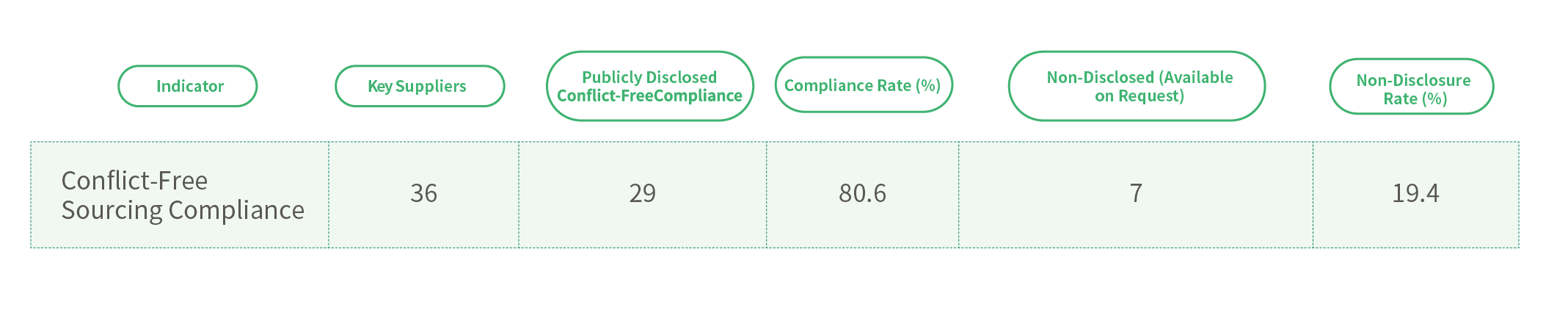

Conflict Minerals Sourcing and Traceability Mechanisms

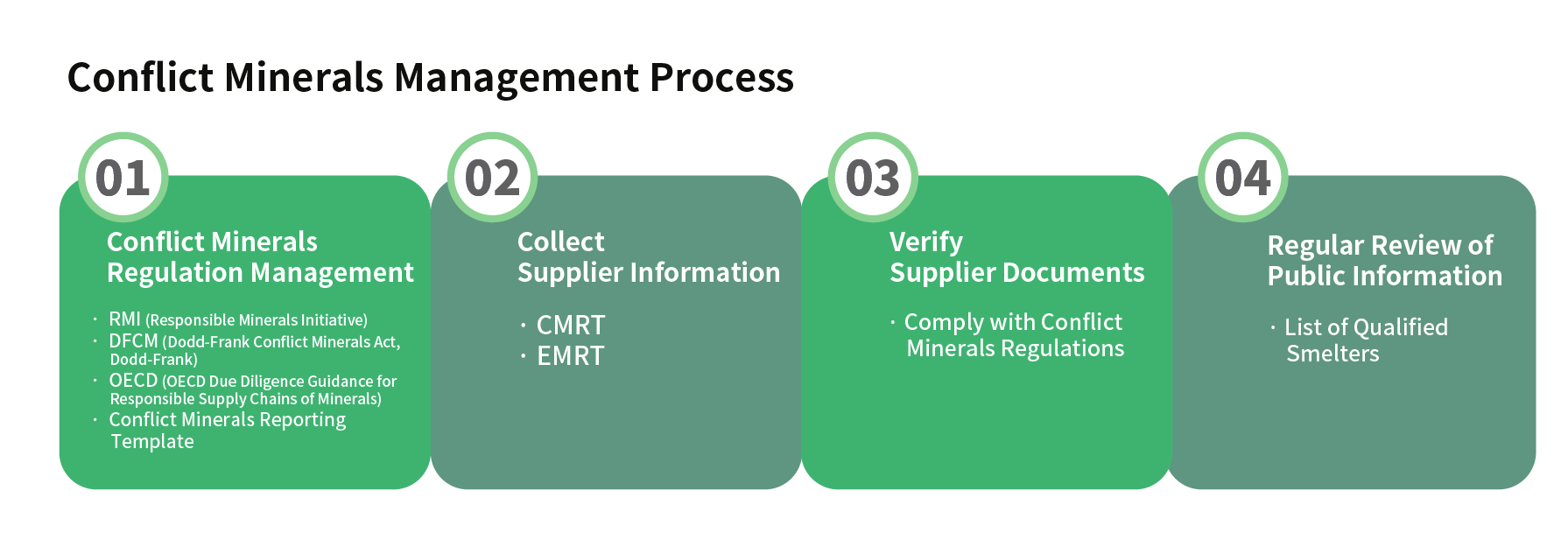

Referencing international concerns about conflict minerals from regions with human rights issues, in order to uphold the universal values of humanitarianism in the supply chain, WT published a Conflict Minerals Policy on its website in 2023. This policy mandates that all major suppliers comply with the U.S. Securities and Exchange Commission’s (SEC) conflict minerals regulation, Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act (DFA). Suppliers must fully disclose the sources of conflict minerals used in their manufacturing processes, including gold (Au), tantalum (Ta), tin (Sn), and tungsten (W) (collectively known as 3TG), and confirm whether these materials originate from non-compliant mines in the Democratic Republic of Congo and neighboring regions.

Survey results indicate that the products supplied by suppliers contain conflict minerals such as gold, tantalum, tin, and tungsten. WT actively monitors updates from the Responsible Minerals Initiative (RMI) regarding smelter assessments to obtain the latest versions of conflict-free documentation (Conflict Minerals Reporting Template – CMRT, Extended Minerals Reporting Template – EMRT, and Additional Minerals Reporting Template – AMRT). In alignment with customer requirements on conflict minerals policies, WT requests CMRT, EMRT, or AMRT reports from suppliers to ensure full supply chain compliance.

As of the end of 2024, WT tracked 36 key suppliers, with the following compliance rates:

|

|